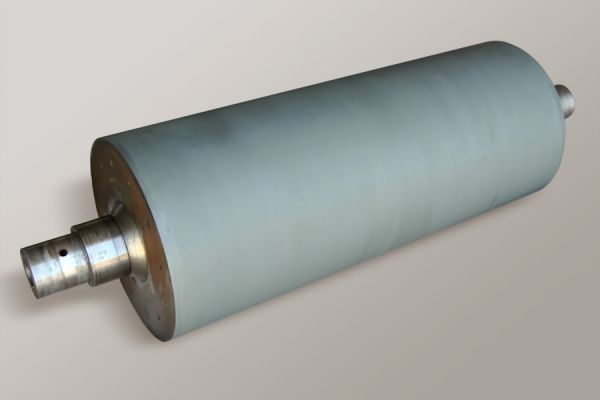

PLASMA SPRAY COATINGS

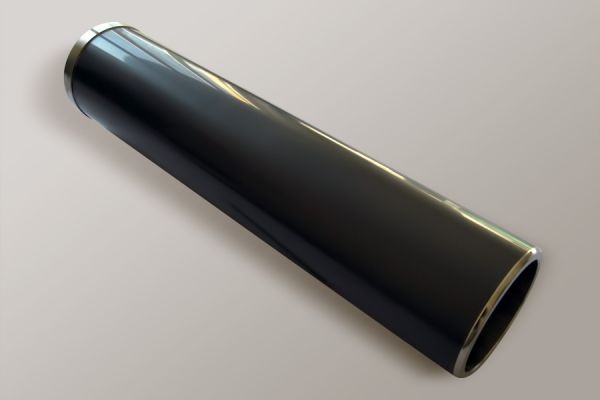

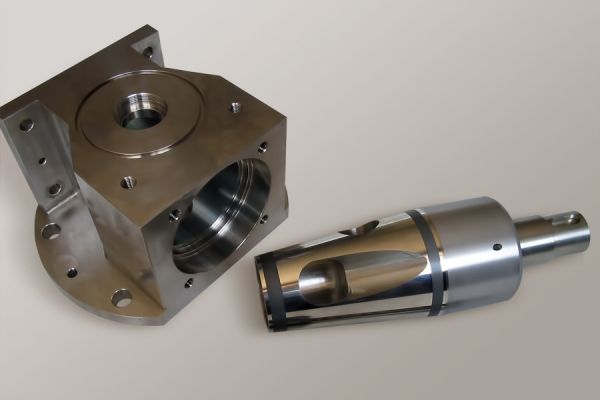

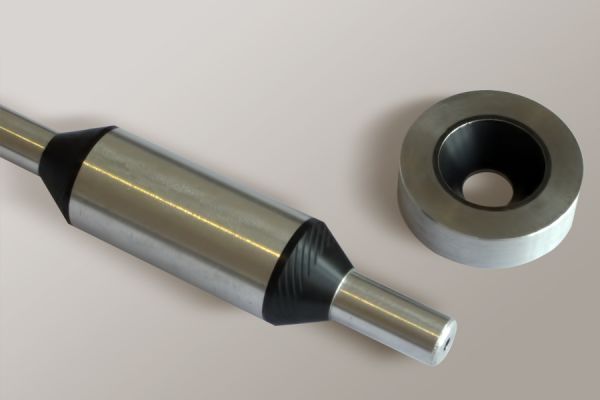

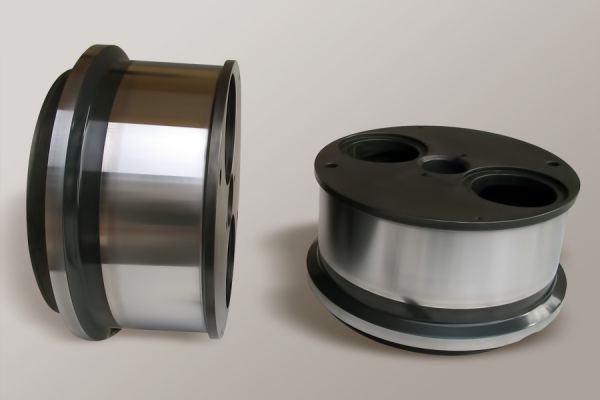

This is a carry-over process that offers technologically advanced results due to its particular characteristics.

A flame composed of nitrogen/hydrogen, argon/hydrogen comes out of the nozzle of the Plasma gun, at a temperature varying between 10,000° and 22,000°C and a speed between 400 and 960 m/sec. A high-pressure powder feeder sends a flow of powder into the hottest zone of the Plasma fluid by means of an inherent gas. The powder melts instantly and is projected at very high speed against the work piece.

Despite the high temperature, the filler material does not alter or sublimate, as the residence time in the plasma fluid is very short.

The coating thus obtained is a cold coating because the work piece, preheated to between 100° and 160° C, is kept at this temperature throughout the treatment.

This high-tech process is all computer-controlled, which allows us to store data, which can be recalled at a later date, even for similar parts.

A flame composed of nitrogen/hydrogen, argon/hydrogen comes out of the nozzle of the Plasma gun, at a temperature varying between 10,000° and 22,000°C and a speed between 400 and 960 m/sec. A high-pressure powder feeder sends a flow of powder into the hottest zone of the Plasma fluid by means of an inherent gas. The powder melts instantly and is projected at very high speed against the work piece.

Despite the high temperature, the filler material does not alter or sublimate, as the residence time in the plasma fluid is very short.

The coating thus obtained is a cold coating because the work piece, preheated to between 100° and 160° C, is kept at this temperature throughout the treatment.

This high-tech process is all computer-controlled, which allows us to store data, which can be recalled at a later date, even for similar parts.